About us

Founded in 2008, Dongguan Mactron Technology Co., Ltd was formerly known as Mactron Technology (Hong Kong) Co., Limited., with two brands: MACTRON and LYUSTEC, specializing in developing, manufacturing and selling of industrial laser equipment system and customized automation devices.

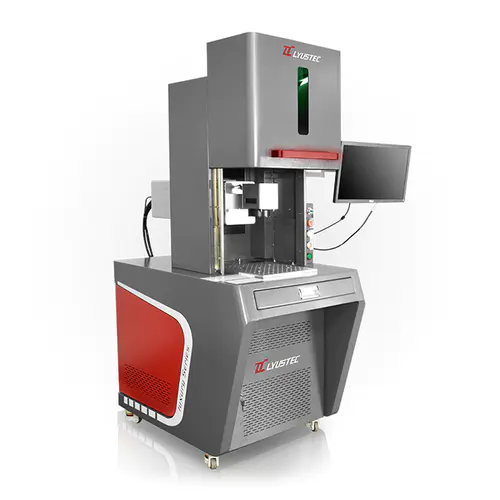

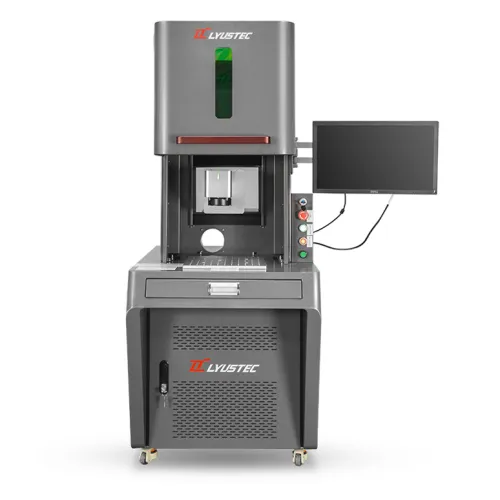

LYUSTEC main products included Fiber Laser Marker, UV Laser Marker, Co2 Laser Marker, 3D Laser System, Precision Laser Cutting Machine, Robot Lasers, Automatic Laser Solutions, etc.

UV ultraviolet marking laser applies high-contrast markings even on sensitive products. As the vector scanning laser impacts the product's surface photo-chemically and with reduced peripheral heating, the heat effect of laser marking on substrates and materials can be kept to a minimum, which is ideally suited for the high-contrast laser marking of sensitive and delicate materials, such as glass, certain plastics (silicone, white polyamides) or ceramics. UV laser markers are used primarily in the automotive and aerospace sectors (cable marking) and in medical technology (catheters, insulin pumps).

Advantages of UV Laser Marker

|

Less Impact on Product UV laser marking system only colors the surface instead of foaming the material, There fore it is possible to mark even highly sensitive and previously unmarkable material with UV laser marker. |

Precision Excellent beam quality of <1.2M². Industrial grade rigid machine, ultra-fine laser beam with high-quality optical lens, to ensure the high precision of laser processing. |

|

Performance Safety and integrity for sensitive and critical materials. filigree, high-contrast markings. |

Reliable Using built-in DSP chip set, equipped with industrial embedded operating system, running MacMark laser marking software, while ensuring superior performance, the equipment is more stable and reliable! |

|

Safety Fully equipped Germany Siemens electrical system, machine complies with EU safety regulations (performance level D) |

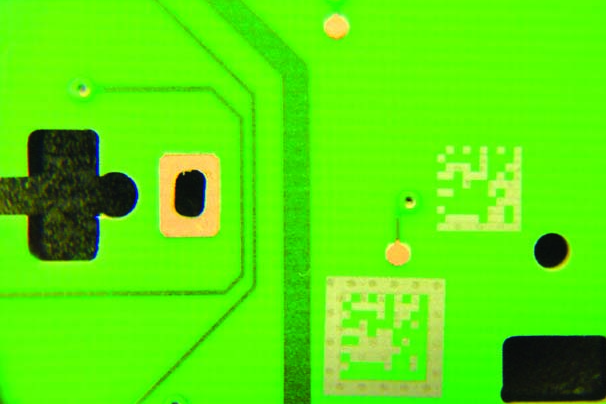

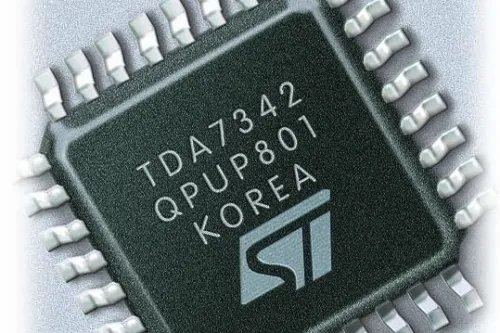

Application of UV Laser Marker

UV laser marker is suitable for marking on the vast majority of metal and non-metal materials, especially for the high-end market of ultra-fine processing.The UV laser marker marks on the surface of packaging bottles of cosmetics, drugs, food and other polymer materials, fine marking effect, clear and permanent marks, superior to ink jet printing and pollution-free; flexible PCB plate marking, scribing; silicon wafer micro hole and blind hole processing; LCD smart glass QR code marking, glassware surface drilling, metal surface coating marking, plastic buttons, electronic components, gifts, communication equipment, building materials, etc.

Featured Products

Collection about lyustec

User Reviews

What users say about lyustec

Frequently Asked Question

Do you have any question?

Yes, the UV laser marker can ensure hyperfine marking on electronic components, glasses, cosmetics, medical equipment and other products.

UV laser marker can produce permanent marks on materials such as glass, plastic, etc. The marking cannot be removed except by destroying the surface of the product.

We introduce international advanced production technology, and strictly implement a series of measures of quality and cost control to ensure the quality of laser marking machine. In addition, all raw materials are strictly inspected in accordance with international standards before they are put into production.

Our updates and blog posts

UV laser marker | High precision uv laser marking machine

UV laser marker has a small heat-affected area and can effectively avoid material damage. It is suitable for ultra-fine marking, engraving, and cutting of materials with a high thermal radiation response.

UV laser marker | Application of uv laser in enterprise processing field

UV laser marker can processing product without any damage to the material. Mass production can also be achieved by adding an automation system to ensure quality and efficiency.

UV laser marker | Glass uv laser marking machine

Because many materials (including glass materials) have better absorption rates for ultraviolet lasers, non-contact processing is used to prevent the glass from being damaged by external forces.

.jpg?imageView2/1/w/500/h/500/format/webp)